AI Pricing: Value and Pricing of Digital Twins

Steven Forth is a Managing Partner at Ibbaka. See his Skill Profile on Ibbaka Talio.

Digital twins have become one foundation of digital transformation for the manufacturing sector. Many manufacturers have invested in the development of digital twins and are taking them to market.

In this post we look at the basic characteristics of digital twins, how they create value, and how that value can be priced. The origins of digital twins go a long way back. One argues that computers have long been used to build models of the world and that digital twins are an application of this to manufactured devices.

Major software platforms, such as Microsoft Azure, have invested in frameworks and development environments for digital twins. See Azure Digital Twins.

Download Ibbaka’s Latest: The AI Monetization in 2024 Research Report

The digital twin is the foundation of many other technologies and as discussed at the end of this post, enables many new revenue streams for manufacturers.

Servitly’s vision of a digital twin architecture. See Digital Twins are transforming manufacturing - an interview with Servitly’s Stefano Butti

3 Types of Digital Twin

Let’s start with a simple definition (from Wikipedia) …

A digital twin is a digital model of an intended or actual real-world physical product, system, or process (a physical twin) that serves as the effectively indistinguishable digital counterpart for practical purposes, such as simulation, integration, testing, monitoring, and maintenance.

There is more than one type of digital twin. The type of digital twin provided will have an impact on how value is modeled and priced.

Digital twin prototype (DTP)

A Digital Twin prototype consists of the designs, analyses, and processes that realize a physical product. The DTP exists before there is a physical product. Many CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) such as Autodesk, Bentley, Dassault, and PTC offer DTP solutions.

Digital twin instance (DTI)

A Digital Twin Instance is the digital twin of each instance of the product once it is manufactured. The DTI is linked with its physical counterpart for the remainder of the physical counterpart's life. This is the realm of manufacturers. More and more products of all types are now connected to digital twin instances.

Digital twin aggregate (DTA)

Digital Twin Aggregation is the aggregation of DTIs whose data and information can be used for interrogation about the physical product, prognostics, and learning. The specific information contained in the digital twins is driven by use cases. This is the realm of systems vendors like ABB, Siemens, and GE are all active in digital twins.

Characteristics of digital twins

Connectivity

One of the most important characteristics of digital twins (in the DPI and DTA flavors) is that they are connected to the Internet, in other words, digital twins are a key part of the Internet of Things. Connecting physical devices to the Internet so that they can share data and receive instruction is central to many digital twin value drivers.

Homogenization

Data about physical events can come in many forms, sometimes this data is very difficult to compare and make sense of. Understanding data requires models. Digital twins provide a model for the data collected about equipment and its operating environment. As a result data can be gathered, analysed, compared in context, and insights derived.

Machine learning AIs consume a great deal of data and engineers spend a great deal of time normalizing and tagging that data. With a well-designed digital twin, the data comes in the form needed.

Reprogrammable

As digital twins are software objects they are by nature reprogrammable. What is more important is that they can provide a way to reprogram and configure the physical objects they are twinned with. This leads to the emergence of many new use cases and ways to create (and share) value.

Digital trace making

One of the problems with unconnected devices is that they do not leave traces of their past use and performance. By connecting a device to a digital twin, in the DTI pattern, one can record the history of the device’s performance. This is what makes possible predictive maintenance, but it also opens new pricing and monetization models for manufacturers. This goes beyond the device as a service, or servitization, to pricing based on device performance.

Modular

Modularity adds enormous value to virtual and physical systems. This is the main lesson of the foundational book Design Rules: The Power of Modularity by Kim Clark and Carliss Baldwin (MIT Press, 2000). Digital twins can give manufacturers the insights they need to develop modular systems and then iterate to improve modules and apply the modular operators. In this way, digital twins are an enabling technology for sustained innovation.

Uses of digital twins

The use cases for digital twins are closely associated with the three patterns: DTP, DTI and DTA. Use begins with design, goes from design to configuration, and then to monitoring, prediction and optimization.

Design - CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) are well established software categories and all of the major platforms enable the development of digital twins. Developing a digital twin as part of the design process is common. Think of 3D printing, where there is a back and forth between the digital design and its rendering. This allows many more designs to be explored and opens the possibility of new approaches to design design verification and design validation.

“During design verification, you verify that your design outputs meet your design inputs. In other words, did you design the device right? During design validation, you prove that the device's design meets the user needs and intended uses you've specified.”

There is an issue here though. The limitations of the design tools, and of digital approaches generally, can limit what one can imagine building to what the design tools afford.

Configure - Having a digital twin makes it possible to explore and test far more configurations than is possible when dealing with physical devices. As the number of configurations of even simple systems have a combinatorial explosion it is useful to have a digital twin to explore and where necessary constrain possible configurations. The CPQ (Configure Price Quote) platforms being added to many CRMs originated as implementations of constraint-based reasoning to prevent sales from selling configurations that could not be delivered. Digital twins can take this much further.

One can go beyond this and connect the digital twin to the physical device and use the digital twin to control the configuration of the physical device. This is what enables the feedback loop from optimization to configure in the above value chain diagram.

Monitor - Data without a model to interpret it is noise. The digital twin is the model that makes data collected from the device meaningful. Instrumenting equipment and connecting the data gathered to a digital twin gives insight into the current state of the equipment and the conditions it is operating under. This can drive value in many ways:

Provide alerts on the current state - to see if any actions need to be taken

Give insights into the operating environment - to understand the real conditions under which equipment needs to perform

Enable the prediction step in the digital twin value chain

Predict - This is one of the most common high-value uses of digital twins. It is often focused on maintenance and is referred to as ‘predictive maintenance.’ Maintenance costs can be minimized and downtime all but eliminated if maintenance is only carried out when needed but is carried out before failure. Value drivers include

Lower maintenance costs

Longer equipment life

Less downtime

Better planning and operations optimization

Optimize - This is the ultimate goal of the digital twin approach. It pulls together the ability of digital twins to monitor their performance and operating environment, to predict performance, and to dynamically configure equipment. There are two feedback loops here. The immediate one is from optimize to configure, but optimize also feeds back to design.

Value drivers for digital twins

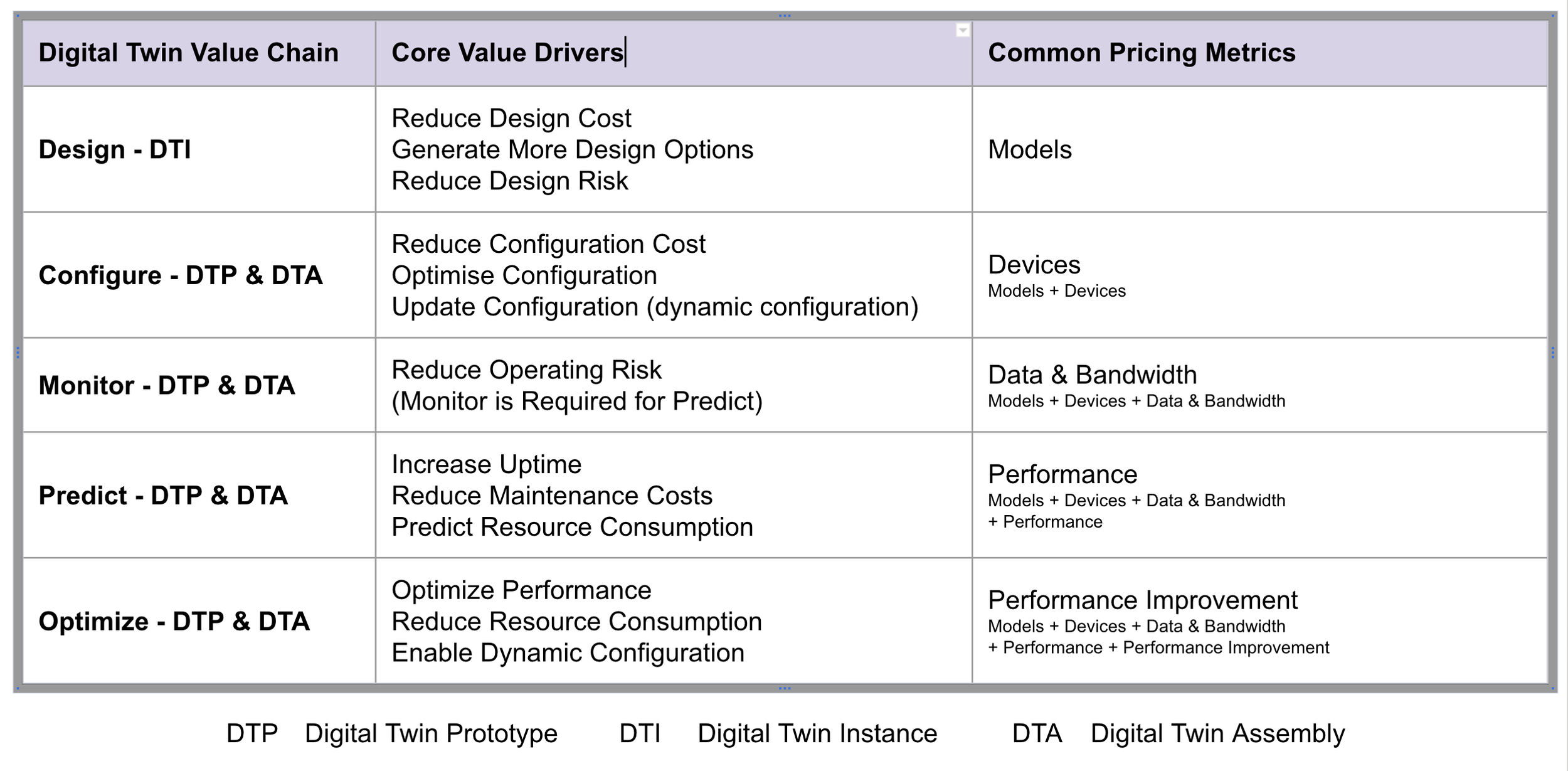

Ibbaka bases pricing on value models and it builds value models from value drivers. The following table summarizes the core value drivers for digital twins at each stage of the value chain and identifies a few of the most common pricing metrics.

The greatest value is created by combining the value created at each step of the digital twin value chain and then aligning price with that value. Value builds across the value chain. Notice how the pricing metrics move from the virtual (models), to the physical (devices), to the connected (data and bandwidth) to performance and finally performance improvement.

Digital twins are the path to performance based pricing for manufacturing.

New revenue models

Part of the attraction of digital twins for manufacturers is that they enable new revenue models. Basic manufacturing, even of sophisticated precision equipment, is becoming commoditized as new production technologies are adopted globally. Beginning with NC (numerically controlled) machine tools and on through new additive manufacturing (3D printing) approaches manufacturing is becoming more and more digital and at the same time more commoditized. Manufacturers are looking for new revenue streams and digital twins are a key enabler.

The Italian software company Servitly (see our interview Digital Twins are transforming manufacturing - an interview with Servitly’s Stefano Butti) refers to this as a Digital Product-Service System. See What is a DPS (Digital Product-Service) system?

Digital twins and DPS systems make it possible for manufacturers to offer subscription models and to better monetize everything from configuration and implementation to service and maintenance.

For example, configuration can move from being a one-time implementation to an ongoing subscription service that continually adapts to the operating environment. The data monitored by digital twins can also identify opportunities to sell additional equipment or upgrades in a manufacturing equivalent of the Product Qualified Leads (PQL) that are popular in B2B SaaS product-led growth models.

Equipment that comes with a digital twin is generally more valuable than the equipment by itself. When value-based pricing is applied there are chances to increase prices and to realize more revenue over time.